Zero waste: maximum efficiency

Embracing the zero waste approach in production

Embracing sustainability, we ensure the responsible reuse of all post-industrial waste by integrating it into our 11-layer cast coextrusion films, fostering a circular economy. Our commitment to a 'Zero Waste Operation' has led to the inclusion of up to 12% post-industrial resins in our Amilen and Nextflex films. We are dedicated to increasing this percentage, thereby enhancing environmental conservation, minimizing plastic waste, and reducing our carbon footprint.

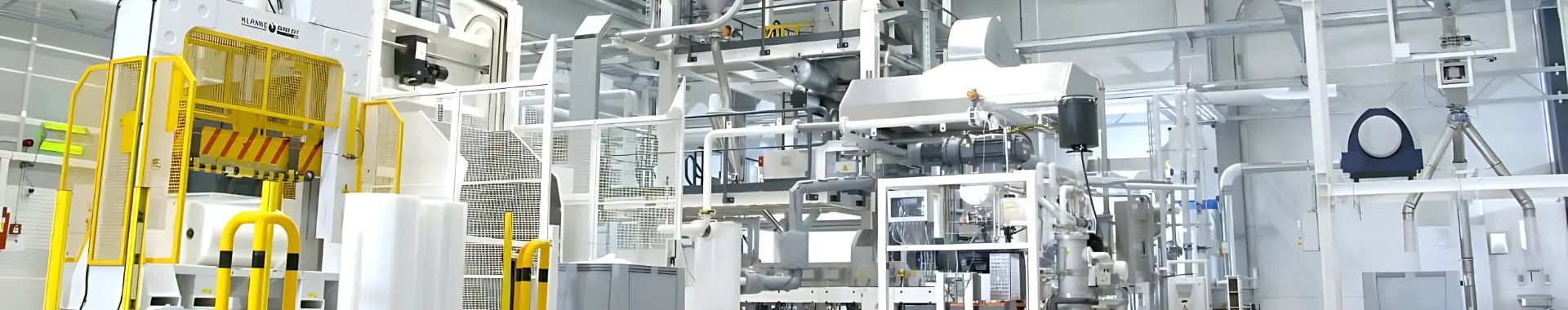

Efficiency in production: less weight, less waste

Our ethos, 'less weight equals less waste,' drives us to produce sustainable plastic films for the food industry. As early adopters of 11-layer cast co-extrusion technology, we've achieved a material reduction of at least 20%, surpassing traditional extrusion methods.

Streamlined energy management

Our company's ethos has always prioritized energy and environmental stewardship. Our continuous drive for efficiency is a cornerstone of our philosophy, evidenced by our DIN EN ISO 50001 certified energy management system since 2011. We focus on technological advancements while prioritizing energy and material efficiency. Our dedication has led to a 14,000-ton CO2 reduction and a 17.6% improvement in specific energy consumption. Our team's engagement with the energy management system is vital, fostering ongoing progress towards a more efficient, zero-waste future.