The world of heat treatment

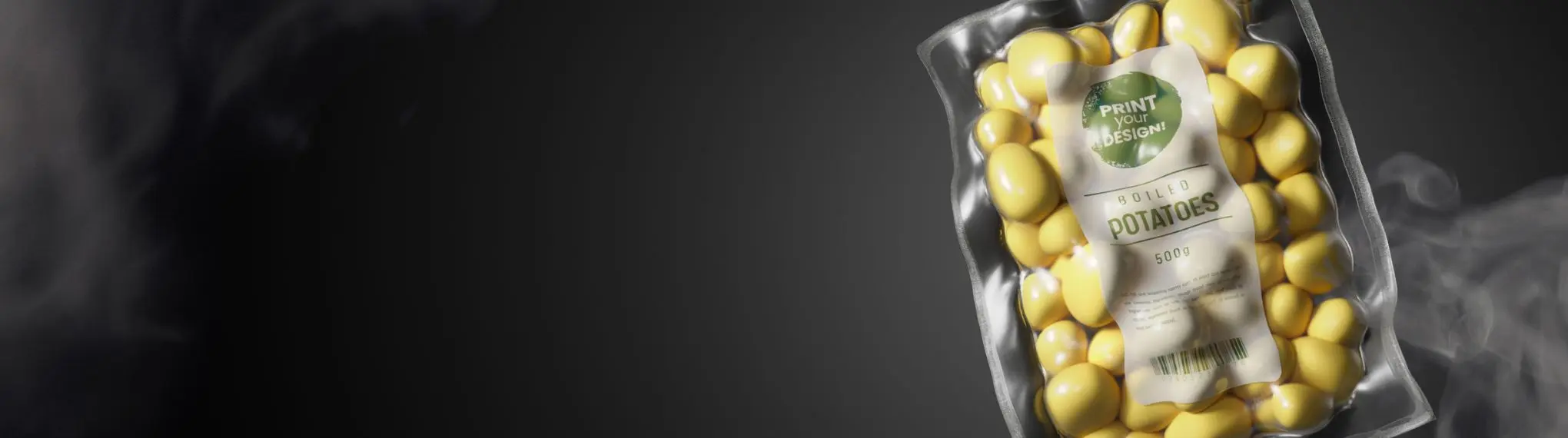

Preserve flavor and quality: explore our heat-resistant packaging solutions

Packaging is essential in food preservation, maintaining product freshness and extending shelf life without compromising flavor or quality. In order to slow down or halt the natural deterioration of food, pre-packaged foods undergo heat treatments like pasteurization, sterilization, and sous vide. Discover our range of heat-resistant films and pouches, enduring temperatures up to 121°C, ensuring culinary integrity from kitchen to table.

Pasteurization

Through pasteurization, the packaged product is heated to max. 90°C for a set time. By removing heat-sensitive pathogens like yeasts and molds, shelf life can be extended.

Sous vide cooking

In sous vide cooking, food is first vacuum-sealed and then being cooked at temperatures up to 100°C. This eliminates heat-resistant microorganisms and allows pre- cooking dishes, considerably reducing the cooking time for the final customer.

Sterilization

Sterilization subjects food, especially vegetables and vegan options, to high temperature until 121°C, to significantly extend shelf life. All pathogens are eliminated. High temperature treatments do not impede printing on the film: your packaging can be personalized with vibrant prints by using special inks which prevent post treatment color changes.