Understanding Recyclability

The concept of recyclability encompasses a material's or product's capacity to be recycled, meaning it can be collected, processed, and reintegrated. By focusing on recycling, we pledge to foster sustainable practices that contribute to the circular economy and lessen environmental impact.

Criteria for Recyclability

According the Plastic Recyclers Europe, a material is recyclable if it meets specific conditions to ensure its reprocessing in a sustainable and economically viable manner.

- Program Support: The product should be composed of a plastic that is not only sortable for recycling but also holds market value or is mandated by recycling legislation.

- Recycling Streams: It must undergo sorting and accumulation into established recycling streams.

- Recycling Capability: The material should be compatible with existing commercial recycling operations, allowing it to be processed into new products.

Mechanical recycling: the second life of plastics

Mechanical recycling transforms waste into secondary raw materials without altering their fundamental structure. Through advanced sorting—both automated and manual—materials are separated to ensure homogeneity. Cutting-edge technologies like NIR spectroscopy, laser, and X-ray techniques are employed to attain the highest purity of recyclates. Post-cleaning and milling, the materials are melted and regranulated, primed for various plastic conversion technologies.

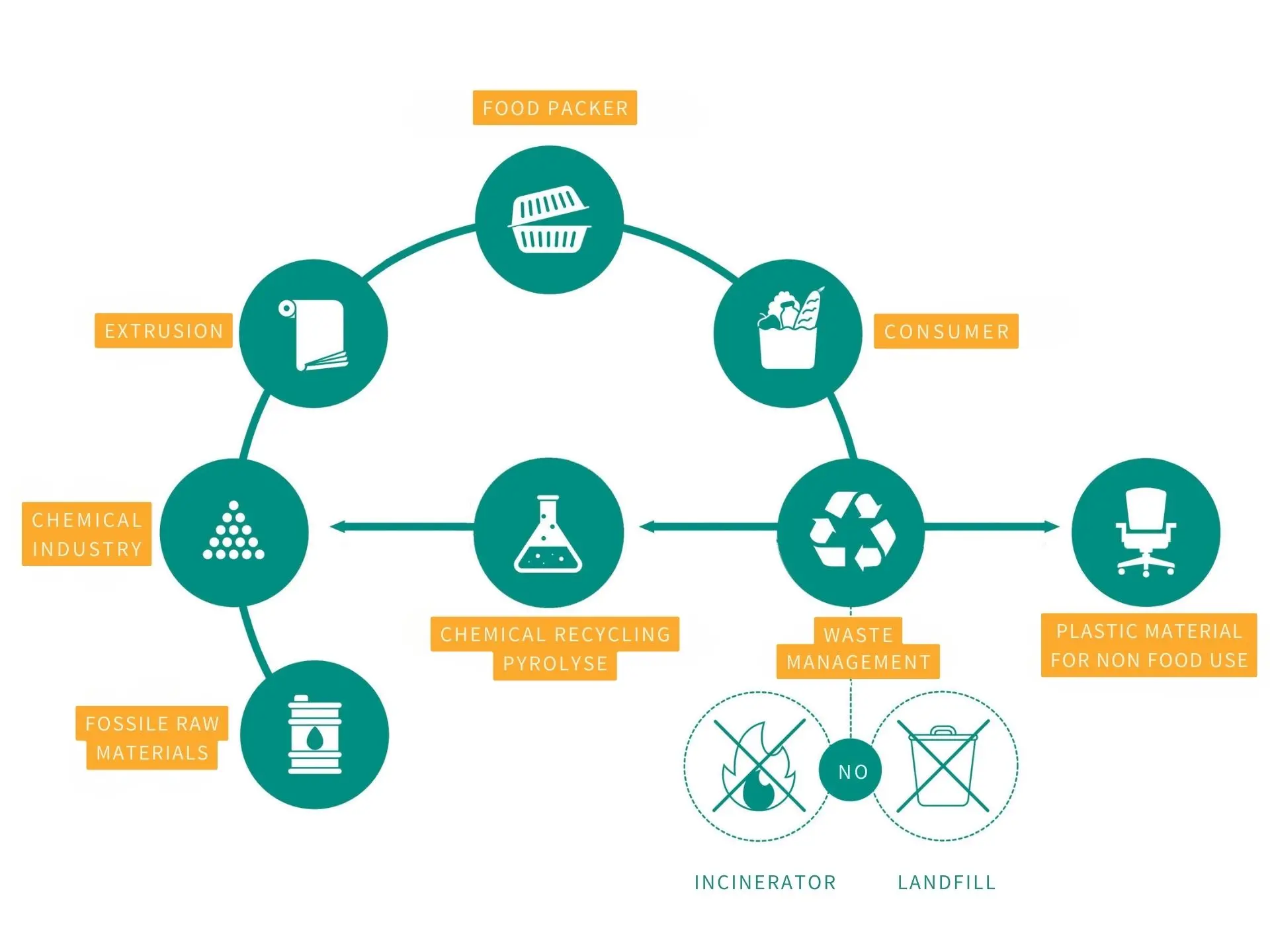

Chemical recycling: closing the loop is the future

Chemical recycling, a collective term for state-of-the-art processes, turns post-consumer plastic waste into precious chemicals for the chemical industry's use. Processes such as pyrolysis, gasification, and catalytic reforming transform waste into monomers and hydrocarbons, the building blocks for new, food-grade plastic products. Across Europe, pioneering pilot plants are advancing chemical recycling, exploring novel methods to sustainably manage plastic waste.