Our production processes: Crafting excellence from raw material to finished product

Bridging German precision and Italian creativity, our supply chain excels from raw materials to the final product. We seamlessly integrate the production process, transforming resin into versatile films and custom-printed pouches, fueled by a synergy of creativity and cutting-edge technology. Our team's diverse expertise drives our collective growth.

The extrusion process

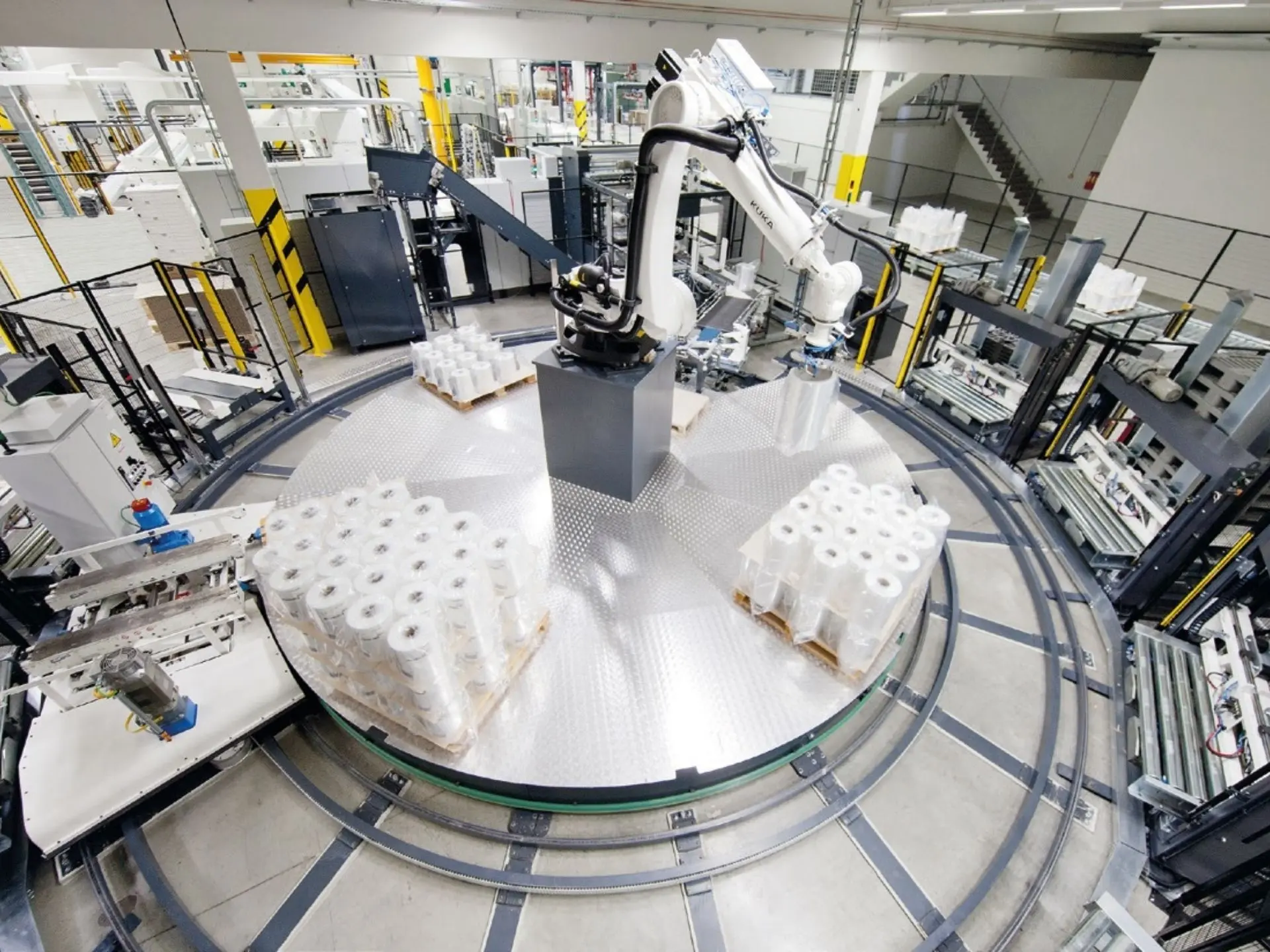

Automation is key

Tailored to perfection, our mother reels are slit precisely to meet customer needs before seamlessly transitioning to our automated packaging line. Here, state-of-the-art robotic systems handle palletization, packaging, and labeling, excluding cross-contamination. Our cutting-edge ERP management system meticulously records every aspect of production, ensuring seamless traceability from resin to reel.

Lamination: crafting custom solutions

The lamination process allows us to meet specific requirements by combining two or more films with different specifications. We employ both solvent-based and solventless adhesives, ensuring durability even under heat treatments up to 121°C.

Efficiency and precision: from film to pouch

On our high precision machines, exclusively Made in Italy, we annually produce 300 million flat or single-fold vacuum pouches, embossed pouches, and embossed rolls. With a commitment to quality ingrained in every step of our process, we ensure that each pouch meets the highest standards of food preservation, providing reliability and freshness to our customers worldwide.

Embossed pouches for easy vacuuming at home

Embossing tailors the film for different applications than smooth ones, facilitating vacuuming on machines with external suction for domestic use. Our embossed pouches are available in small packaging units.

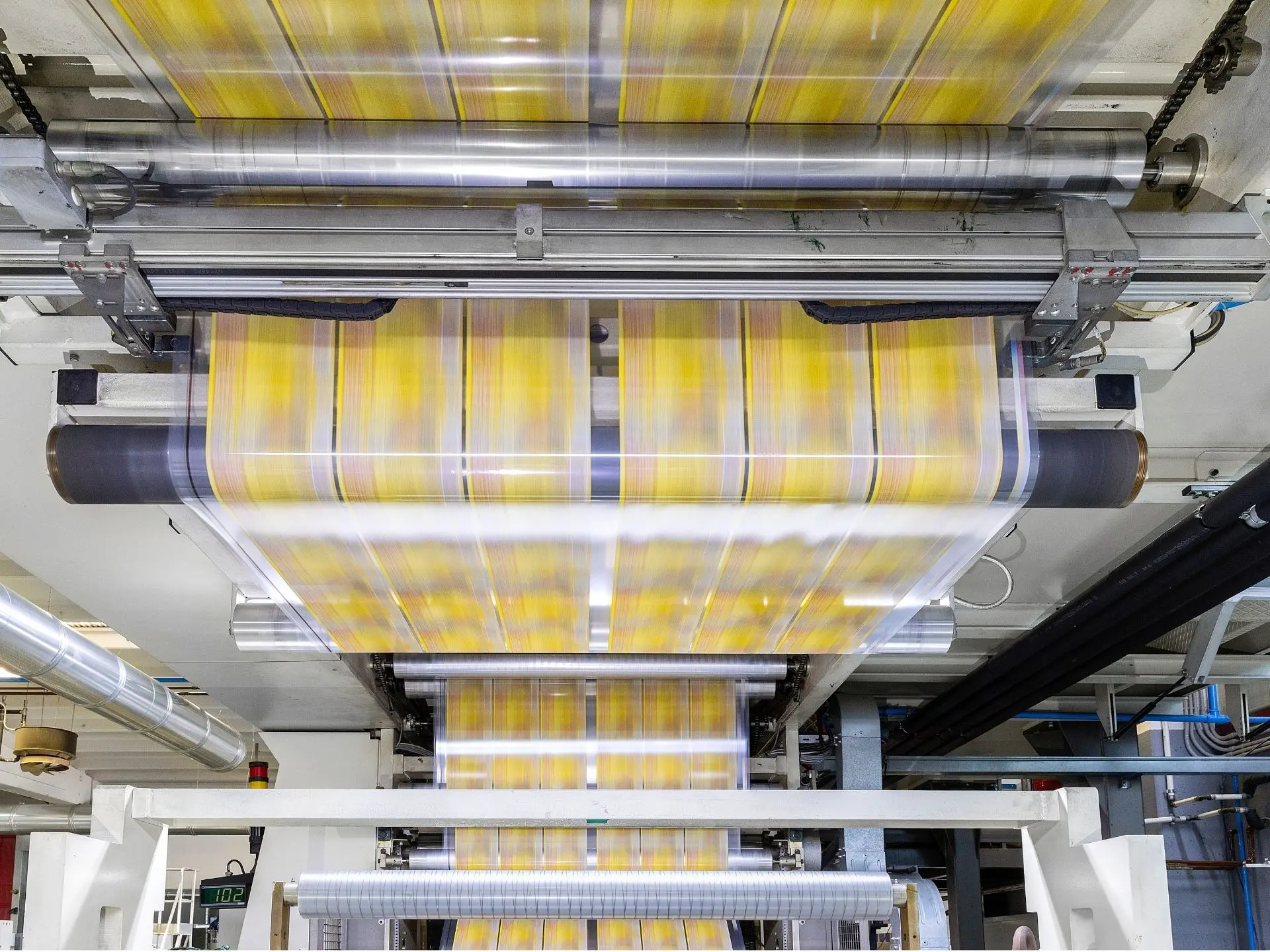

Next level flexography

At Niederwieser, we believe that flexographic printing technology is the ideal solution to meet the market demands for smaller production runs and faster lead times. Our advanced printing process offers exceptional precision and versatility, making it perfect for flexible films and vacuum pouches.

We ensure seamless transitions between external and internal printing, accommodate both small and large production runs, and provide everything from single-color to vibrant 10-color printing.